AZAD Engineering to Invest Rs.500 crores on the 3rd lean manufacturing plant in Hyderabad – lays foundation stone on site

Hyderabad (Telangana) [India], November 23: Azad Engineering Pvt Ltd, a Hyderabad based market leader in Precision Engineering, a company that caters to the Energy, Aerospace, Heavy Machining, and Oil & Gas Global OEMs, is in the process of setting up its 3rd state-of-the-art lean Manufacturing Facility & Centre of Excellence of Global Standards at Tunki […]

Hyderabad (Telangana) [India], November 23: Azad Engineering Pvt Ltd, a Hyderabad based market leader in Precision Engineering, a company that caters to the Energy, Aerospace, Heavy Machining, and Oil & Gas Global OEMs, is in the process of setting up its 3rd state-of-the-art lean Manufacturing Facility & Centre of Excellence of Global Standards at Tunki Bollaram, Medchal Malkajgiri District of Telangana.

The company recently laid the foundation stone at the site and plans to invest over Rs 500 crores over the next 3 years on this plant. Spanning over an area of 23.45 acres, in a phased manner, this facility will create a one-of-its-kind precision manufacturing eco-system that will feature Uber- Smart, Lean and Modern Shop floors with the most advanced manufacturing technology and will showcase cutting-edge futuristic technologies such as Industrial Artificial Intelligence, Robotics, Digitization, Lean etc. The company is also planning to acquire IGBC Gold Rated Green Building certification for this Plant. The construction of the first phase of 30,000 sq meters will be completed by July 2022. Hence, this facility will be operational by Q2FY23 and will primarily manufacture and export supercritical components for Global OEMs in the Aviation and Power Generation Industry such as GE, Mitsubishi, Siemens, Toshiba, MAN, Doosan Skoda, GE Aviation, BOEING, HONEYWELL, EATON, RAFAEL, BHEL, HAL, Baker Hughes among others. Besides, the setting up of this Plant will benefit the local communities in and around its vicinity as it is expected to create employment opportunities for around 1000 people.

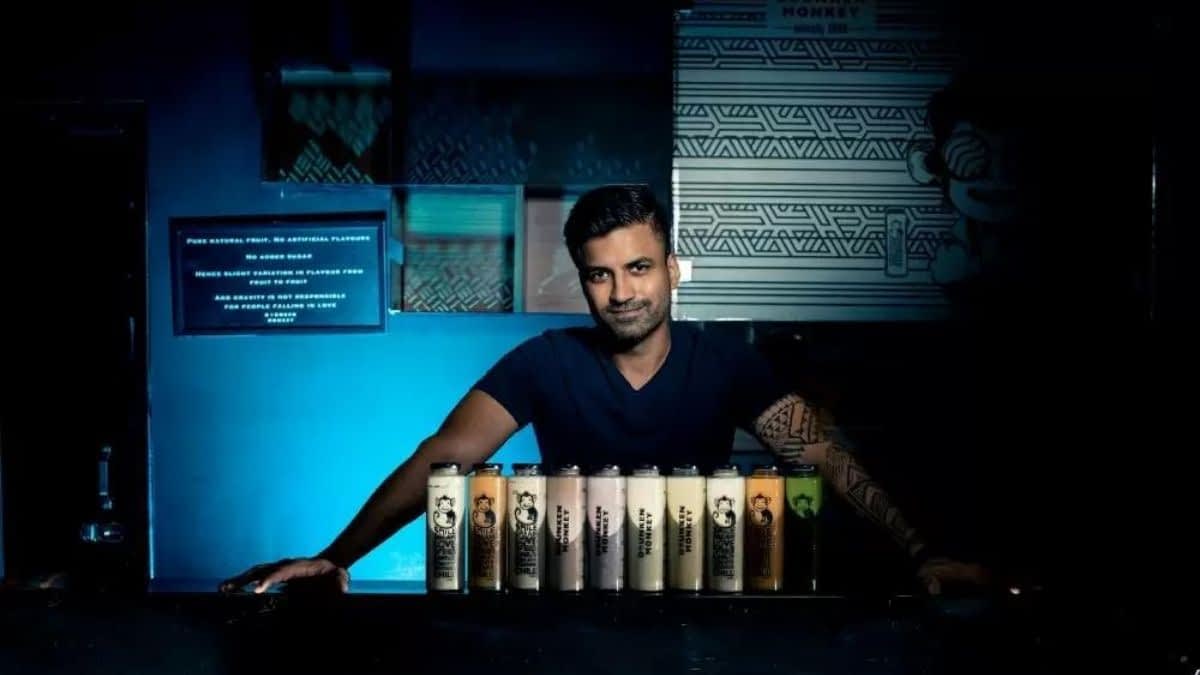

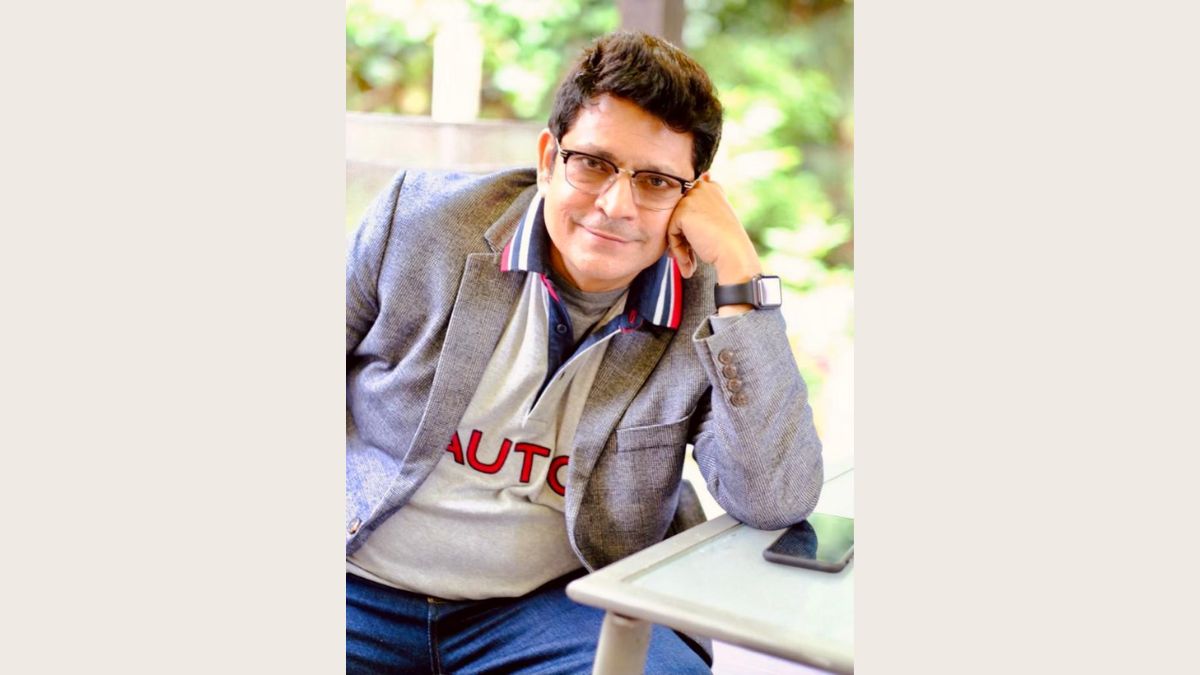

Speaking to the media, Rakesh Chopdar, Managing Director, AZAD Engineering, said, “Setting up this 3rd plant is part of our strategic initiative to significantly scale up our manufacturing operations by investing in world-class, Industry 4.0 lean manufacturing facility to cater to the demand of our esteemed global clientele. We are very excited for this new phase of our growth, and so we are investing in creating a facility that will feature unique capabilities in Precision Forging, Sheet Metal Fabrication, HVOF, TBC, Thermal spray Coating, EB Welding, Chemical processing (NADCAP), Metal Joining (NADCAP), Non-conventional processes (NADCAP), Fluid distribution system (NADCAP), Facility for – ETF / ITF and specialty fasteners, Testing laboratory (NABL) along with Robotics and automation to name a few.

It took us years to clear all the major stringent entry barriers, and now is the time to ramp up the scale of production to meet the demands. AZAD is all set to witness rapid ramp-up in the top line with each of its clients, given the qualification process is already completed and all the business contracts/orders are in place. We are all set to grow a CAGR of over 50% over the next 5 years with an impressive and sustainable bottom line.

AZAD Engineering Pvt Ltd was established in 2008 by first-generation entrepreneur Rakesh Chopdar, Azad Engineering is a world-class manufacturer of highly engineered, complex, and supercritical rotating components for niche turbine and aerospace industry used for Power Generation and Aircraft OEMs. Years of combined experience and relentless pursuit of economical solutions to complex and critical manufacturing challenges have positioned Azad as an industry leader with a clear monopoly in India & catering to the world, Azad is still the ONLY qualified rotating component manufacturer in India for several high-end technology turbines to many OEM’s. Azad, over the last few years, has focused on securing qualifications and today stands qualified for all models and frames for its client base, making it the only qualified partner for its product line from India. A typical qualification process lead time is typically 3-3.5 years for a new entrant, Azad’s focus on qualification has not hindered their healthy CAGR growth of 15% since its inception.

Azad, an end-to-end solution provider, has established itself as a one-stop partner for reputed global power generation & Aerospace OEMs. The company expects to deepen its relationship as a preferred partner and continue to enjoy the flagship position with a new facility coming up over the next 18-24 months.

Earlier in the month of June’21, Azad Engineering had successfully closed its first round of funding of USD 20 Mn from DMI Finance Pvt. Ltd, a Non-Banking Finance Company (“NBFC”) founded in 2008, whose core businesses include wholesale finance.

With a mission to put India on the global radar, Azad Engineering has challenged the current mindset around manufacturing in India to establish India as a one-stop world-class facility & is keen to be the torchbearer of Indian specialized manufacturing for all the end-to-end needs of a global OEM. He envisions transforming the entire manufacturing industry using digital manufacturing and Industrial AI, right from the design process and production floor to the supply chain and administration.